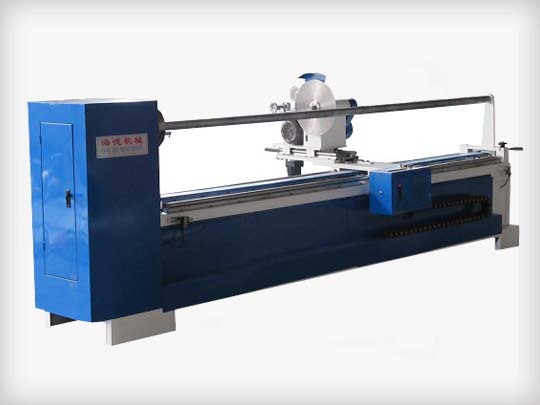

The process characteristics of Longmen cutting machine: in shoe parts materials, in addition to natural leather, but also a large number of applications of synthetic leather, artificial leather, fabric and other materials. Without strict materials these materials uniform, regular shape, blanking, punching and multilayer can. Longmen cutting machine is the process of design and manufacture. In order to meet the need of multi layer punching, the shoe making machine can also configure the automatic feeding mechanism according to the material state, and the multilayer material is added together to enter the working table, so that the production efficiency is greatly improved. Longmen cutting machine is fixed and the lifting of Longmen type, also have manual and automatic punch. Automatic punch machine can be fixed on the knife mold blanking plate, or reciprocating motion of a computer control system for die cutter on the beam and the feeding mechanism of automatic feeding movement, so as to realize the automation of punching. Automatic blanking procedure is: punch blanking punch to the left (or right) to move a knife mold blanking width to table (or raw materials) at the end of the automatic feeding of a knife mold punch length to move in the opposite direction and blanking. In the actual production, the application of automatic blanking technology is less, a large number of use is still manual feeding models.

The structure and performance of Longmen cutting machine: the shoemaking machinery is mainly composed of a hydraulic cylinder synchronization mechanism, transmission mechanism, beam and punch mechanism, stroke control mechanism etc.. The hydraulic transmission mechanism is mainly composed of oil tank, oil pump motor, electromagnetic servo valve, hydraulic cylinder and other hydraulic components. The hydraulic control system adopts the following technology and differential speed increasing circuit, the power of the motor is only. The electromagnetic servo control valve controls four oil cylinders to move at the same time, in order to drive the movement of the lifting beam. In order to ensure the consistency of the motion of the four cylinders, the machine is provided with a toothed plate synchronization mechanism. The cylinder synchronization mechanism is composed of four tooth plate respectively with four cylinder piston rod is connected, and the tooth plate and meshing with each other, forming the whole movement, the four cylinder movement when the load, can maintain the same speed, driving beam blanking reach the purpose of steady motion. The crossbeam and the punch mechanism comprises a beam, cylinder piston rod, sliding punch parts etc.. Four oil cylinder piston rods are respectively fixed on the four corners of the transverse beams, and the supporting beams are supported and driven. Rolling bearing punch in beam rail to punch and punch material for sliding around, Aluminum Alloy, the manipulation of light and flexible punch. When punching the shoes, punch on the plane and beam guide plane and cutter blade plane, table plane to keep a high parallelism, to ensure cutting die stress uniformity and blanking quality shoes. Hand rotation hand wheel, can control the electromagnetic reversing valve mechanical direction, so that the distance between the beam and the working table can be adjusted, and to maintain the balance of the oil tank two oil chamber at the height of the adjustment of the beam. The stroke control mechanism is composed of a handle and a fine adjustment button, a stroke fine adjustment knob and a control element in the electric control box. Punching, as long as the hands handle and the button on the beam and the punch is rapid downward punching blanking, once completed, the return beam and punch to the upper limit position. The accuracy of the fine adjustment control stroke makes the shoes with different thickness both convenient and accurate when punching. Adjust and use of the machine, and a hydraulic swing arm cutting machine is basically the same.