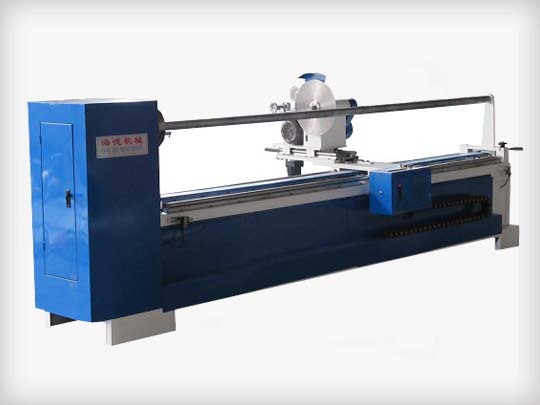

According to the upper parts of different materials, cutting machine is divided into swing arm cutting machine, cutting machine, Longmen plane cutting machine etc.. The cutting machine is the special equipment of shoe shoe material blanking shoe shape parts. Shoe cutting technology is the basis for the development in the manual cutting and cutting on the blade, its working principle is to use the blanking die cutter cutting force, cutting into the shoes, the shoes of different shapes. Various types of cutting machine made by the working principle, not only cutting speed, cutting force, high efficiency, and cut out the shape of the shoes is very accurate, so after cutting shoe parts processing according to the.

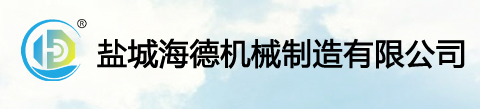

Early cutting machine for mechanical transmission, has the advantages of simple structure, fast speed, convenient maintenance; the disadvantage is vibration and noise, easy deformation and damage of die cutter. With the shoes, standards and environmental standards, cutting machine mechanical transmission has been replaced by hydraulic cutting machine. The hydraulic cutting machine smooth transmission, cutting force, cutting accuracy, low vibration and noise, so development is very fast. In order to meet the increasing varieties of shoe material and shoe production professional needs of the market, cutting machine models are also gradually increased, such as hydraulic swing arm cutting machine, Longmen hydraulic cutting machine, hydraulic plane cutting machine, automatic transport material cutting machine, cutting machine and other program. Cutting machine for punching force. Blanking control cutting machine from the stroke switch control to delay control, electrohydraulic control delay, the blanking is more accurate and more convenient operation.

Cutting machine and cutting die cutting technology has been widely used and developed in the footwear industry, has become the most important processing method, the most popular. But there is no limit to the development of science and technology. In view of the shortage of high cost and fast response ability of the cutter die manufacturing, a new and non cutting die cutting technology has emerged, which is the high energy beam blanking technology and the jet cutting technology. High energy beam is a laser beam, electron beam and ion beam, and the jet is a high pressure water jet. This cutting technology not only needs no knife mold, but also more important is the use of computer control, can be compatible with the system software, to achieve the leather and non leather shoe parts automatic expansion, cutting and blanking. This new cutting technology has been widely used in the industrial field. Although the application in shoemaking industry is still small, but the application shows that this superiority of die cutter cutting technology in die cutter cost, high saving shorten new product production cycle, improve production efficiency and other aspects can not be ignored.