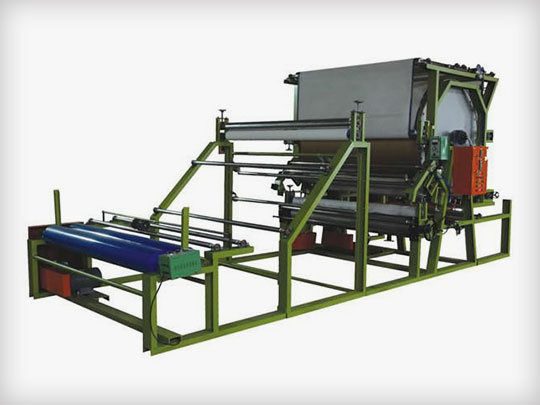

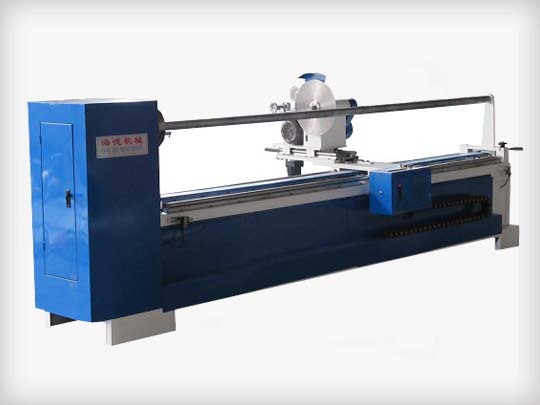

Equipment use and maintenance: according to the production process, product features, equipment performance, operating procedures, such as the correct use and maintenance of shoe-making equipment, is an important task of equipment managers and operators. Before the operator use the equipment, equipment management should carry out technical training of equipment operation and adjustment, process, tooling, safety, maintenance and so on, and by the guidance of qualified and experienced operators to use independent equipment. Because the shoe making equipment, especially the key equipment technology is very strong, complex coefficient and function are different, the user must put forward different targeted requirements, in order to ensure the proper use of equipment, and according to the production process and product characteristics of replacement and installation and supporting equipment, the process performance of the equipment to meet the production efficiency product quality requirements. The equipment daily maintenance and maintenance, is to ensure that the positive measures the normal operation of the equipment and the prevention of accidents, the basic institutions require users familiar with the equipment, abide by the rules of operation, prevent the occurrence of the equipment and personal accident; to master the knowledge of equipment lubrication, ensure lubricating equipment complete, according to the provisions of point, qualitative, quantitative and timing of equipment lubrication. To check and lubrication of the equipment before the class; class in strict accordance with the rules of the use of equipment, observe the running condition of the equipment, found problems in a timely manner or report; to the equipment cleaning and cleaning work, when necessary to fill the log; to keep the tooling accessories and tools, safety protection device complete and effective. Shoe making key equipment is the use and maintenance of key equipment. In the assembly line equipment mainly for injection molding machine, toe lasting machine, stretch after the help of machine or stretch machine, help damp heat setting machine, adhesive pressing machine, nail machine, followed by freezing and shaping machine, setting machine, even after bangkou for injection molding machine, sewing machine, sewing welt inside and outside machine sewing machine etc.. The key equipment in the production of parts of the main hydraulic cutting machine, cutting machine, leather insole molding machine, molding machine, outsole with injection molding machine, mixing machine, rolling machine etc.. These devices are important, not only because of complicated structure, strong manufacturability, high precision, and maintenance difficult, more important is because has a decisive important effect on production efficiency, product quality, production operation and management of fixed assets etc..

Equipment inspection: footwear equipment inspection is mainly for the daily inspection of key equipment, the main contents of the inspection of the equipment is the vibration, abnormal sound, Wen Sheng, pressure, flow, loosening and other phenomena. Inspection, usually from the equipment running in the appearance of the phenomenon, by the senses, simple equipment, the quality of processed products to determine the performance of the equipment and the quality of the work. In particular, the hydraulic and pneumatic transmission of shoe-making equipment due to the complexity of the structure and control system, high manufacturing precision, for the equipment inspection increased the difficulty. But as long as the characteristics of the equipment and products from the quality of the situation to check carefully and rely on experience to judge, equipment inspection will receive a good effect, to provide a reliable basis for maintenance and repair. In the hydraulic transmission device, vibration and noise for oil filter plugging, oil volume, oil viscosity is too high, the end of tubing from the oil surface and oil surface, inhalation of air bubbles, oil pump seal damage, loose tubing and resonance caused by the high temperature; for high viscosity, oil quantity reduce the overflow valve back flow, pump heating, heating element, hydraulic cooler too close from bad work environment temperature, higher oil pressure caused by the shortage; overflow valve and pressure regulating valve is incorrect or damaged, resulting in leakage or oil leakage due to insufficient flow for oil filter; is the mesh is too small or the blockage, leakage of hydraulic components, flow valve or damage caused by improper. In the pneumatic transmission equipment, vibration or noise is not normally open or close the valve, the valve control voltage or control of low pressure, cylinder speed, muffler failure impact due to insufficient pressure; for small caliber valve, valve has condensed water and water filter cartridge valve or a foreign body, or jam, pneumatic components, leakage and other reasons. In the mechanical transmission equipment, vibration and noise for the transmission mechanism of reduced precision and increased clearance, loosening, shock and other reasons; temperature for rolling bearings or sliding bearing friction increases, lack of lubrication, the motor load is too large, the friction clutch is damaged or adjust the bad reasons. According to the characteristics of the production of shoes, equipment inspection time is generally carried out in the equipment running state, also known as online inspection. Through equipment inspection found the problem, to determine the cause of failure, the development of maintenance plans, timely troubleshooting and recovery of equipment performance, equipment management is the main day-to-day work. General equipment inspection by equipment manager, maintenance workers and operators jointly responsible for.

Equipment maintenance: equipment maintenance is an important means to maintain the physical form of the equipment, and the physical form of the equipment is the correct reflection of the true value of the equipment to use the symbol. In shoemaking equipment, shoemaking technology and processes of different types and sizes of equipment is more, conditions of use and utilization are also very different, so the equipment wear, corrosion, fatigue, deformation and aging phenomenon and affect the quality of products is the extent of the inconsistency, and the difference must be carefully analyzed, take the different maintenance methods for maintenance, preventive maintenance and fault maintenance and maintenance of the three main maintenance mode. Preventive maintenance